Apply End Cap

Contact UsLaminate End Cap

The end cap is a separate piece of plastic laminate glued to the raw exposed end of a countertop.

The description below is for a standard post-formed kitchen countertop 25-1/2″ wide, with a 3″ high backsplash. Dimensions of standard kitchen end cap are 5″(W) X approx. 28″(L) X laminate thickness. End caps are cut oversize to allow for trimming with a router and they also are cut for the left and right sides of the countertop.

The build-up strip measures 24″(L) X 1-1/4″(W) X 3/4″(T). The stick for the back splash measures 4″(L) X 3/4″(W) X 1/2″(T).

Basic tools are required that include; a small electric router and flush trim laminate bit, belt sander, power drill, drill bits, fine-tooth hand file, padded saw horses, screwdriver, hammer, and seam roller.

Supplies needed are; contact adhesive, contact adhesive solvent, wood build-up strips, end cap (Fig.1), hot melt glue or wood glue and screws or nails, small brush or roller, petroleum jelly, and rag for clean up.

How to Apply End Cap

- Flip the countertop that is to be capped upside down on a surface that will not scratch the laminate surface, padded sawhorses work well.

- Attach 3/4″ thick build-up strip on edge that gets capped. Methods of attachment can include; hot melt, wood glue, and screws or nails. Photos showing wood glue and screws (Figs 2&3). Apply wood glue then screw, nail, or clamp build-up strip with c-clamps or spring clamps until the glue dries. Also, use some type of padding between the c-clamp and laminate surface. When using nails or screws make sure they are short enough (1-1/4″ max.) so they don’t protrude through the finished side of the countertop. Also pre-drill hole in build-up strip the same diameter as screw or nail.

- Attach the small stick to the back of the backsplash, using the methods described above (Fig.4). This stick is only 1/2″ thick and extends from under the scribe stick-on backsplash to the build-up strip applied previously to create a 90° angle. If attached with nails or screws maximum length is 1-1/8″ long. If nailing use extreme caution. The backsplash must be supported to prevent the cove from cracking when the nail head is struck by a hammer. The cove is the laminate inside radius at the transition point between the countertop deck and backsplash.

- Flip countertop right-side-up.

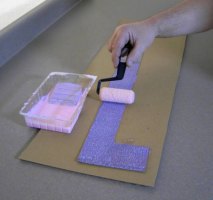

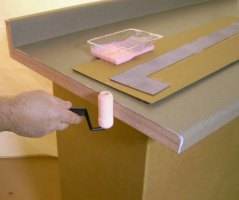

- With a small brush (natural bristle for solvent base, synthetic bristle for water base) or small disposable paint roller apply contact cement (non-flammable solvent base or water base adhesive is recommended) in a smooth even coat to both surfaces (Fig. 5&6). Follow all directions on the glue container. Let the glue dry until tacky then mate both surfaces together (Fig.7), when contact is made the two pieces can’t be moved again. Use a roller (Fig.8) or wooden block (Fig. 9). Example short piece of 2″ X 4″ material used on edge to exert even pressure on the entire glue joint. Be careful not to roll off the edge of the end cap it can crack the laminate end cap because it is not supported from behind. Use extreme caution; if the laminate cracks, the edge can become VERY sharp, and serious injury could result!

- Apply lubrication to the finished surface of the countertop in the area that will come in contact with the flush trim router bit (Fig.10). Petroleum jelly works well.

- Use a small handheld router with a laminate flush trim bit to trim off excess cap material (Fig.11). Move the router in a counter-clockwise direction. Keep the router moving, do not stop in one spot, or burning of laminate is possible.

- File routed edge of end cap at a slight angle to remove any sharp edge and flush edge of the end cap to laminate on the countertop (Fig.12). File TOWARD the countertop surface to avoid chipping end cap.

- Use a rag and solvent recommended by the glue manufacturer to remove any unwanted glue on the surface of the countertop. Make sure not to get excess solvent on the glue line, solvent can loosen the glue bond.

- Flip countertop upside-down on a surface that will not scratch the laminate surface.

- Sand bottom and back of backsplash flush with build-up sticks using a belt sander (Fig.13) or a sanding block. Sand ONLY in direction TOWARD particleboard. Never sand away from the particle board, this can cause the laminate to chip.